DTH Down the Hole Hammer & Bits

DTH Down the Hole Hammer

The optimum range of hole size for blast hole drilling with DTH is 90 mm to 254 mm (3 ½”–10″). Smaller blast holes are generally drilled using tophammer, and larger holes generally use rotary machines.

In other applications, like foundation drilling, DTH hammers can be used with single bit in hole sizes up to . 750 mm (30″). With multiple hammer units CD (Cluster drills) drill holes up to 70″ or 1778 mm.

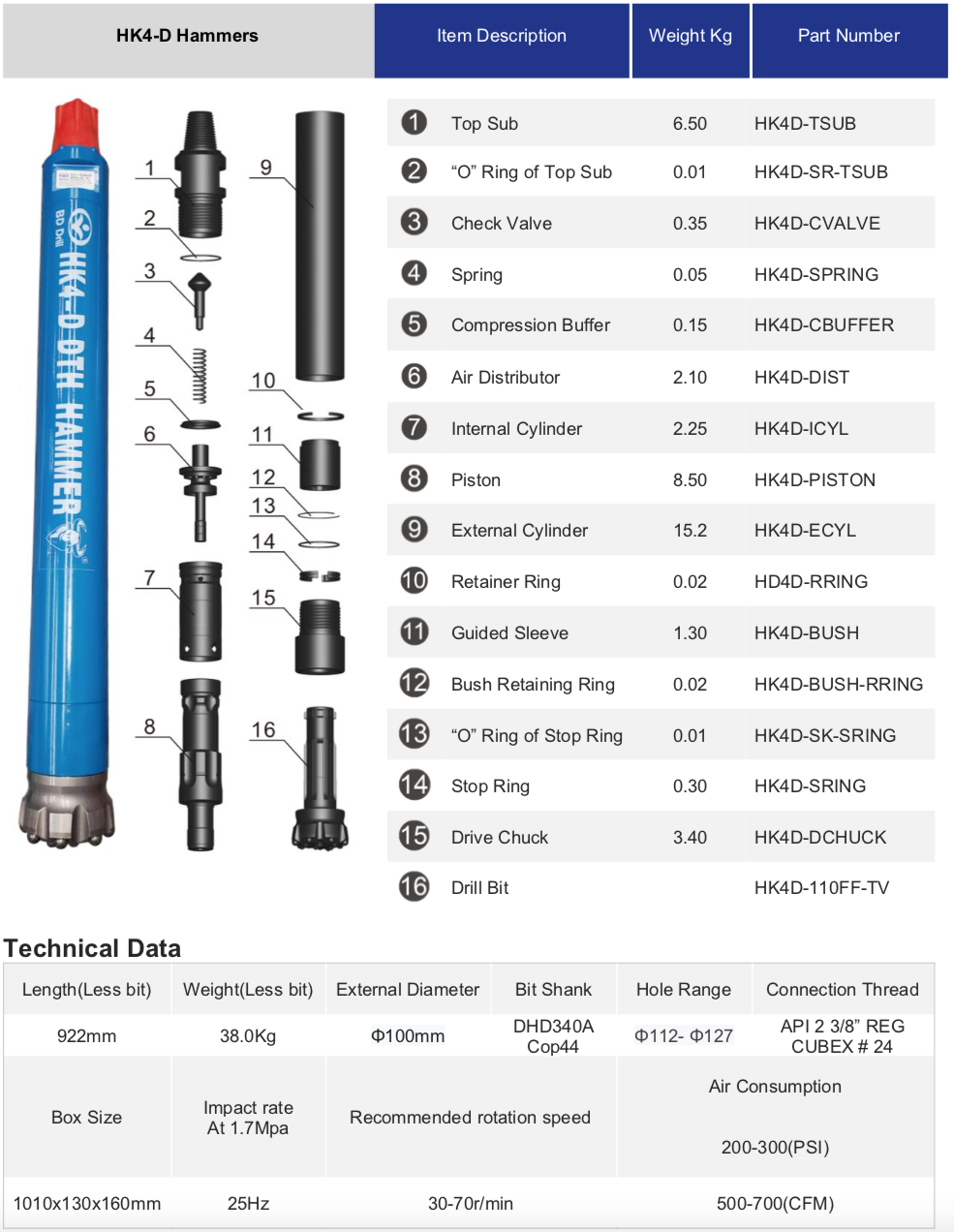

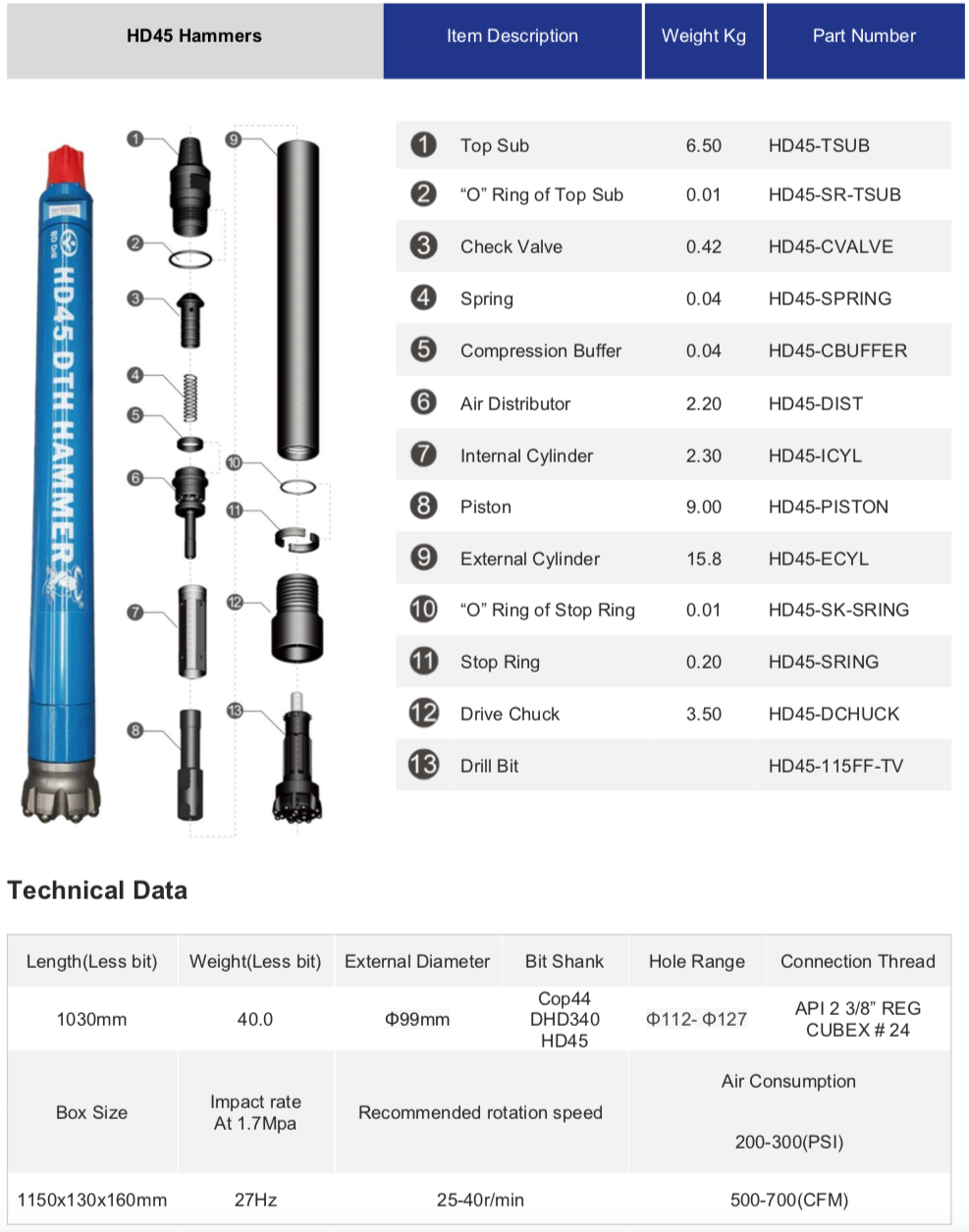

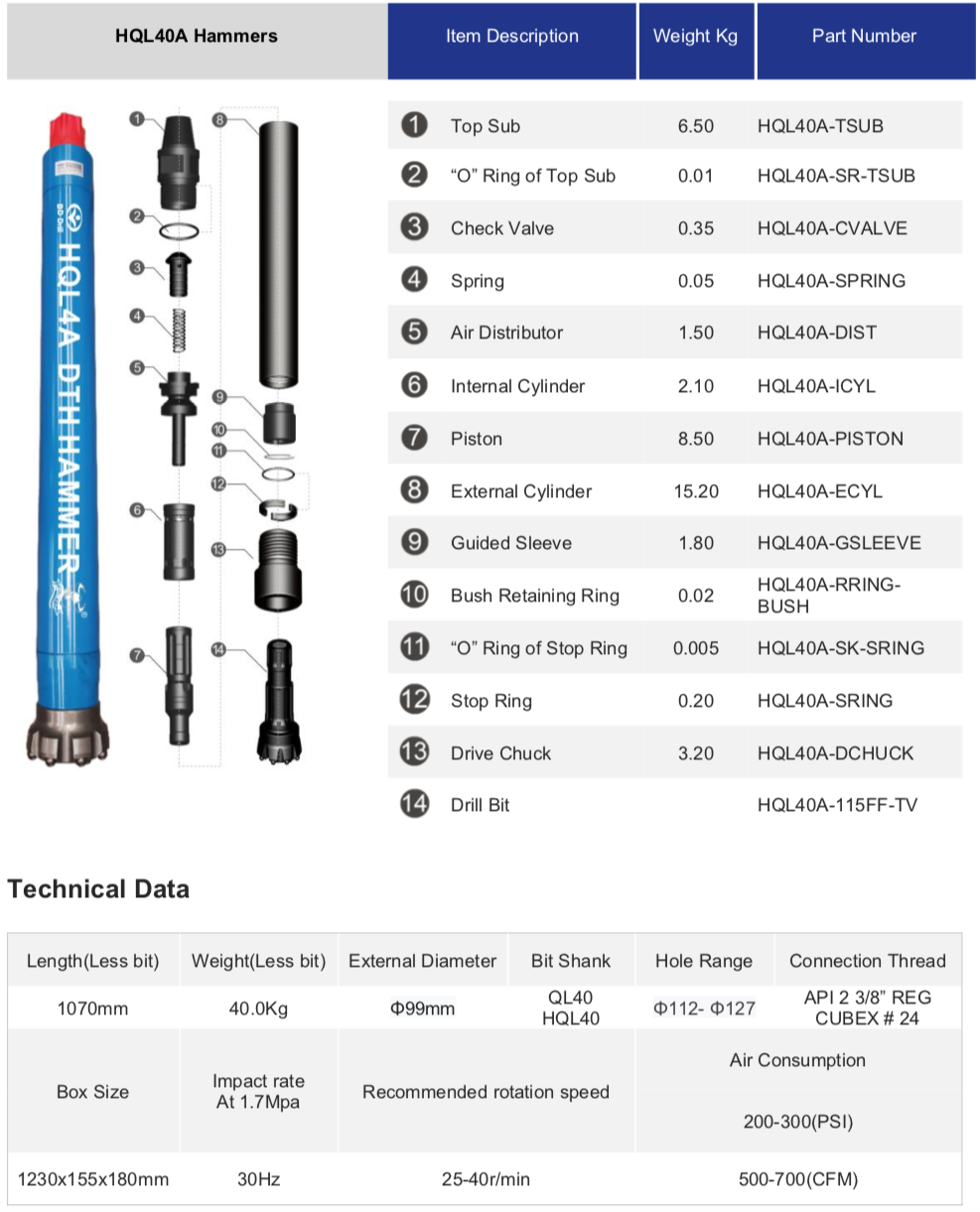

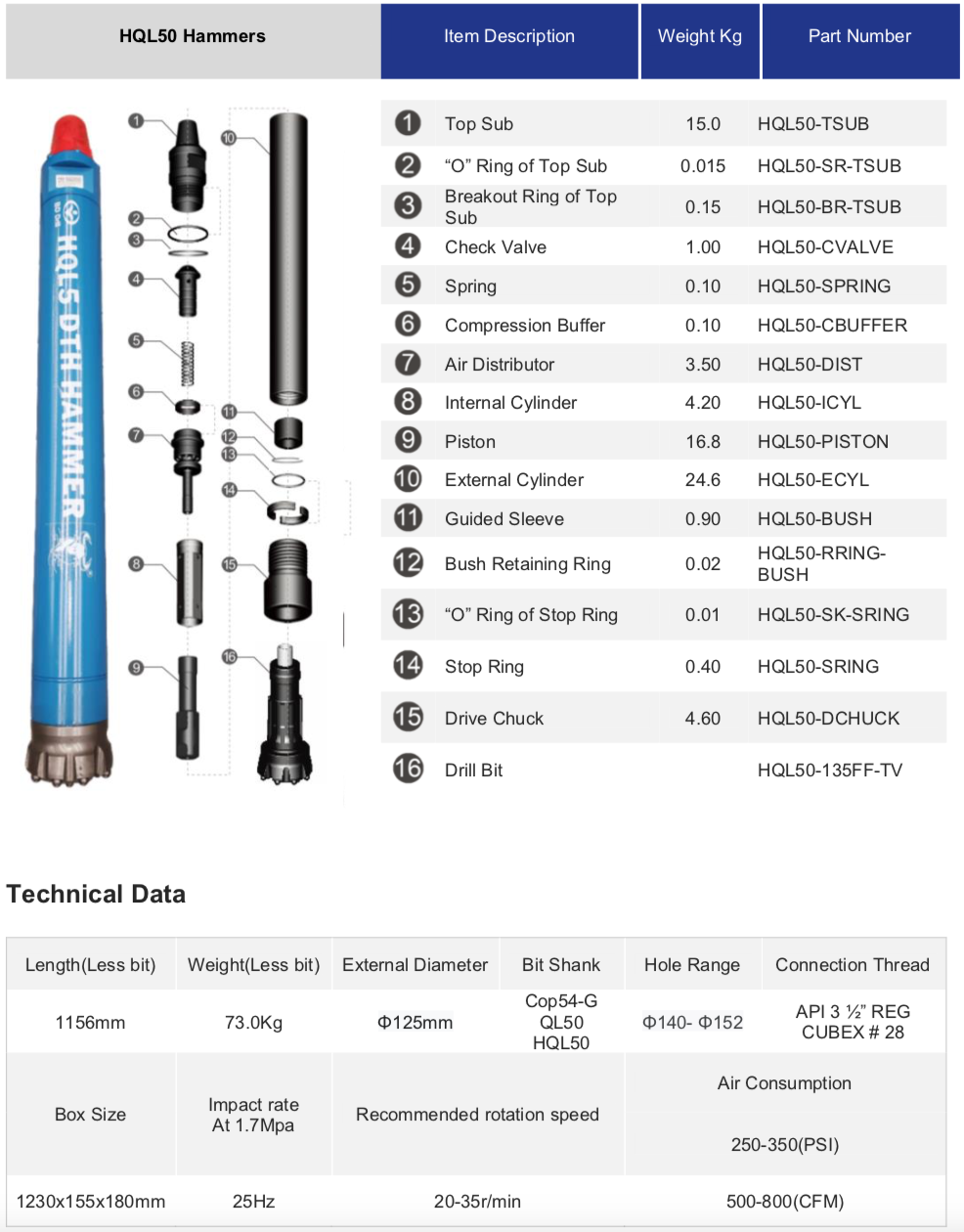

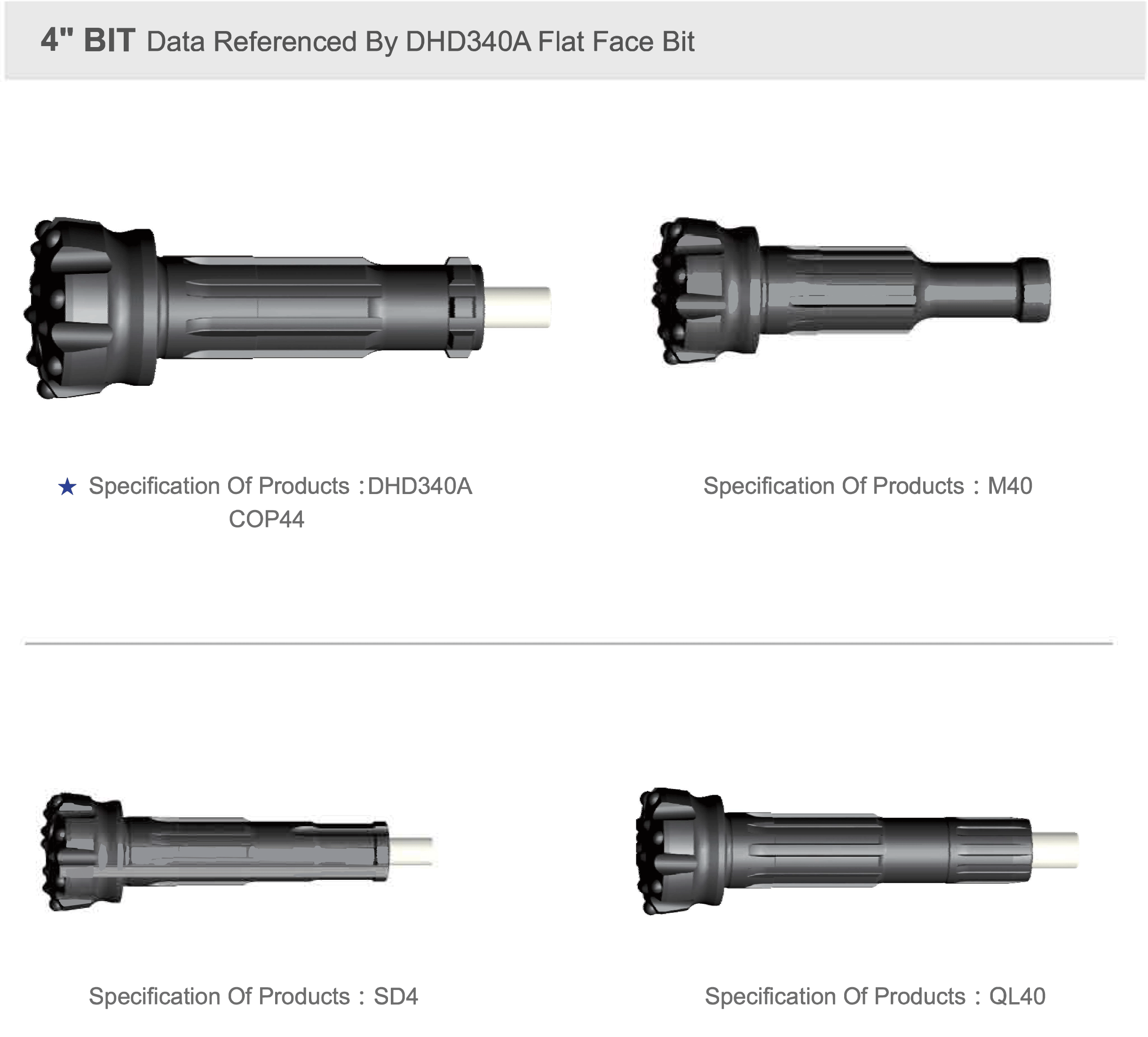

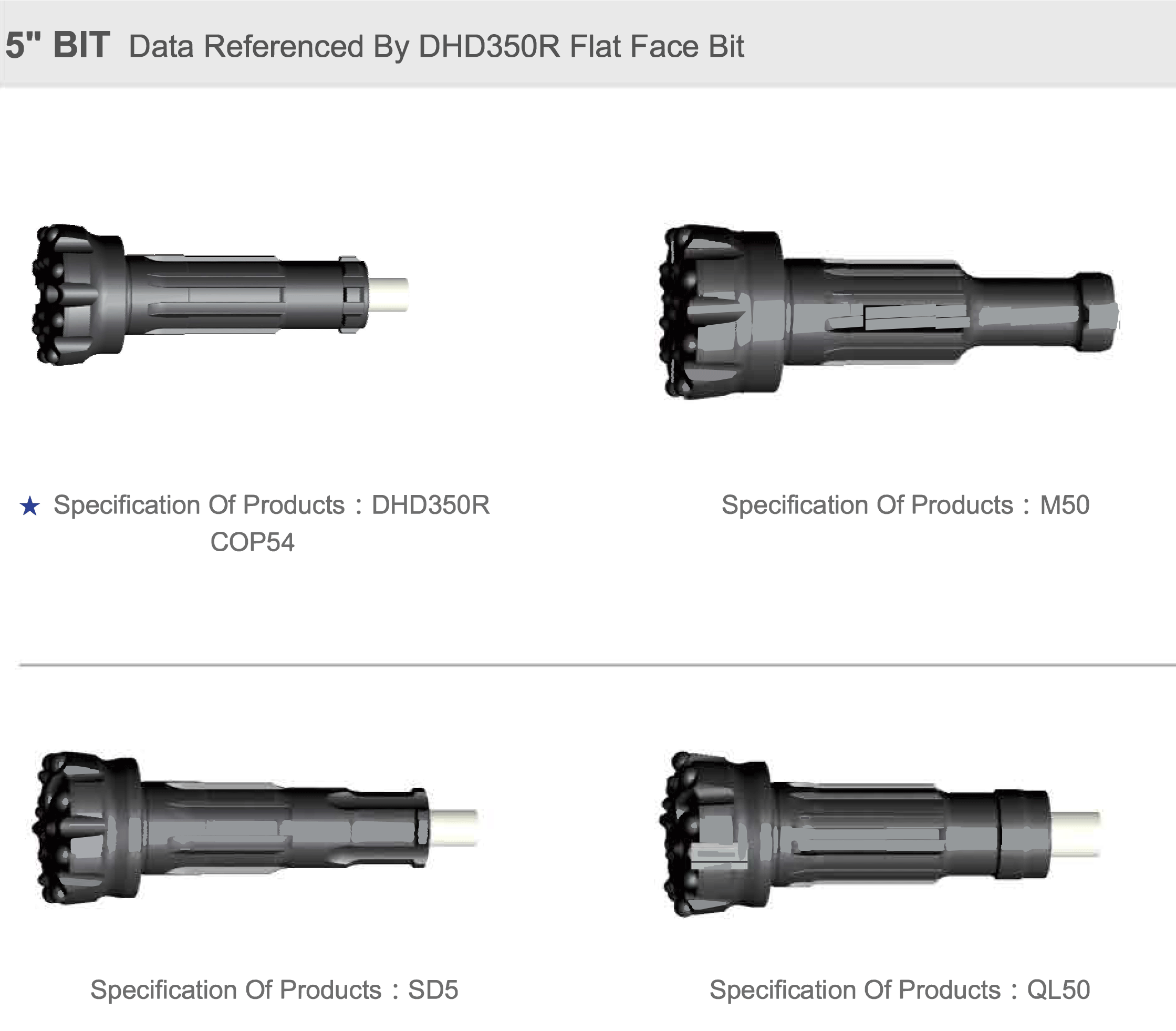

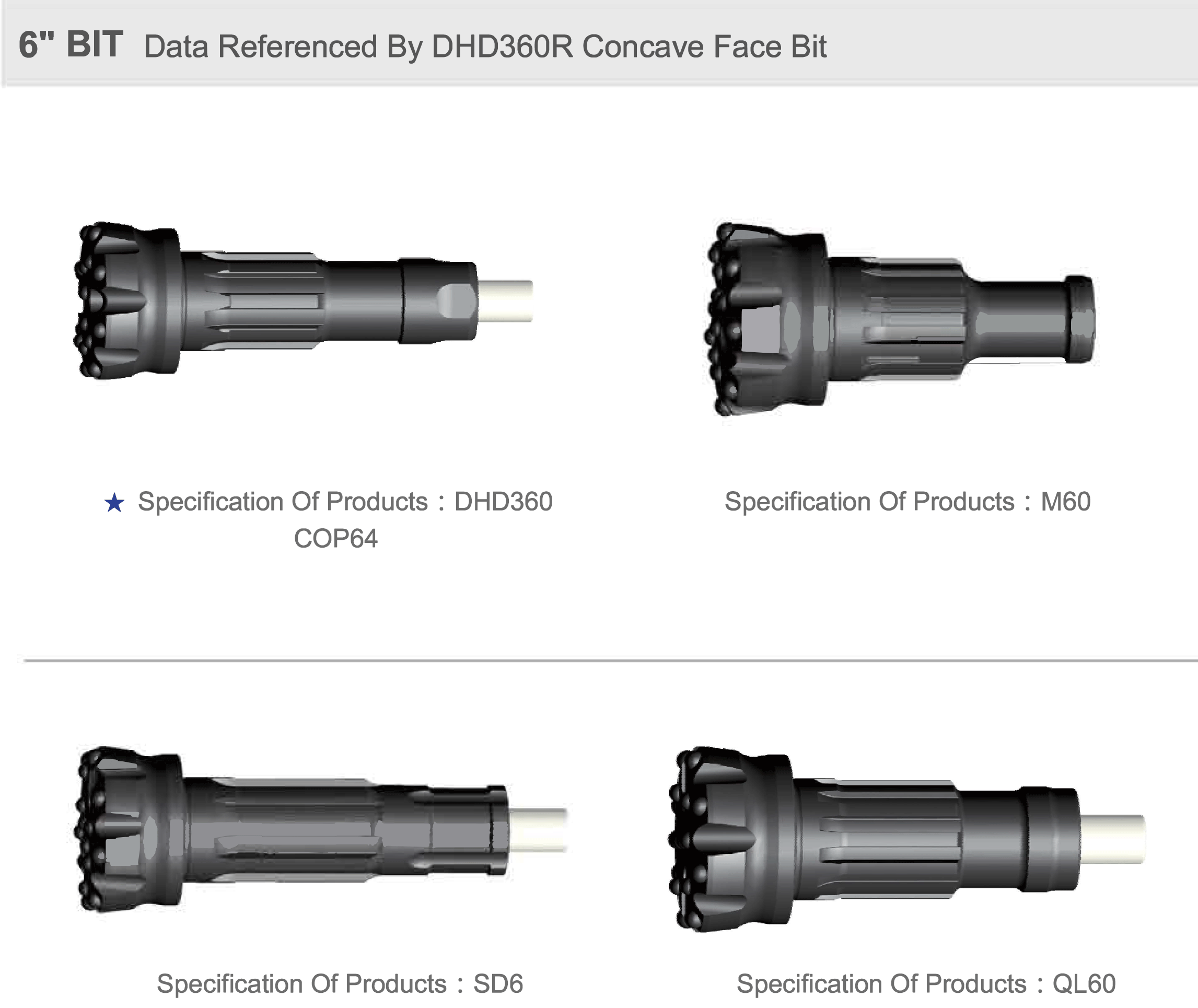

As a rule of thumb, the smallest hole diameter a DTH hammer can drill is its nominal size. A 4 inch hammer will drill a 4 inch (102 mm) hole. The limiting factor is the outside diameter of the hammer, because, as hole diameter reduces, airflow is restricted. Maximum hole size for production drilling is the nominal hammer size plus 1 inch, so for a 4 inch hammer the maximum hole size is 5 inch (127–130 mm).

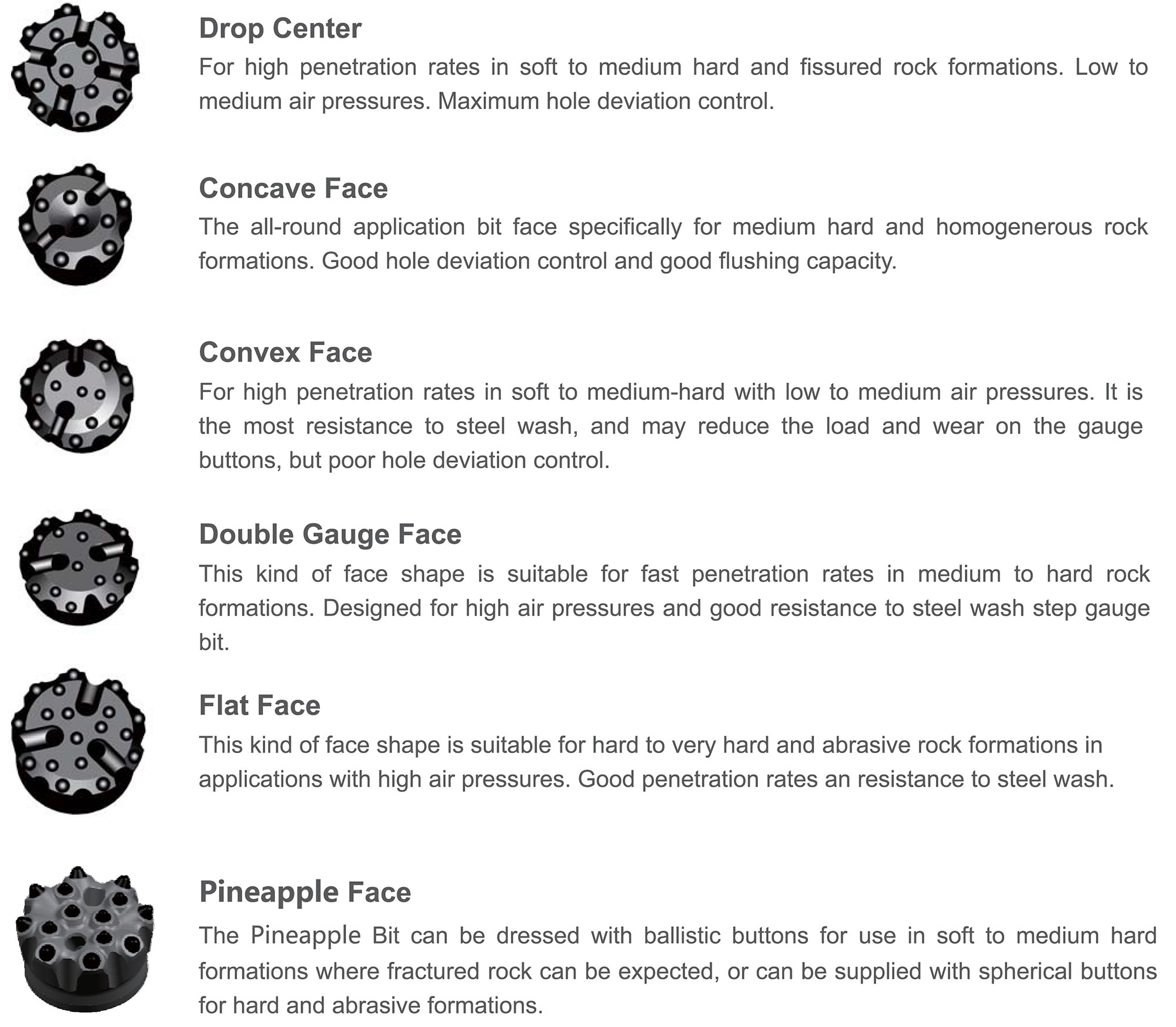

Choosing the right hammer is largely determined by hole size and type of rock formation. Ideally, the size of the hammer should match the required hole dimension as closely as possible, leaving just enough space for cuttings to evacuate the hole.

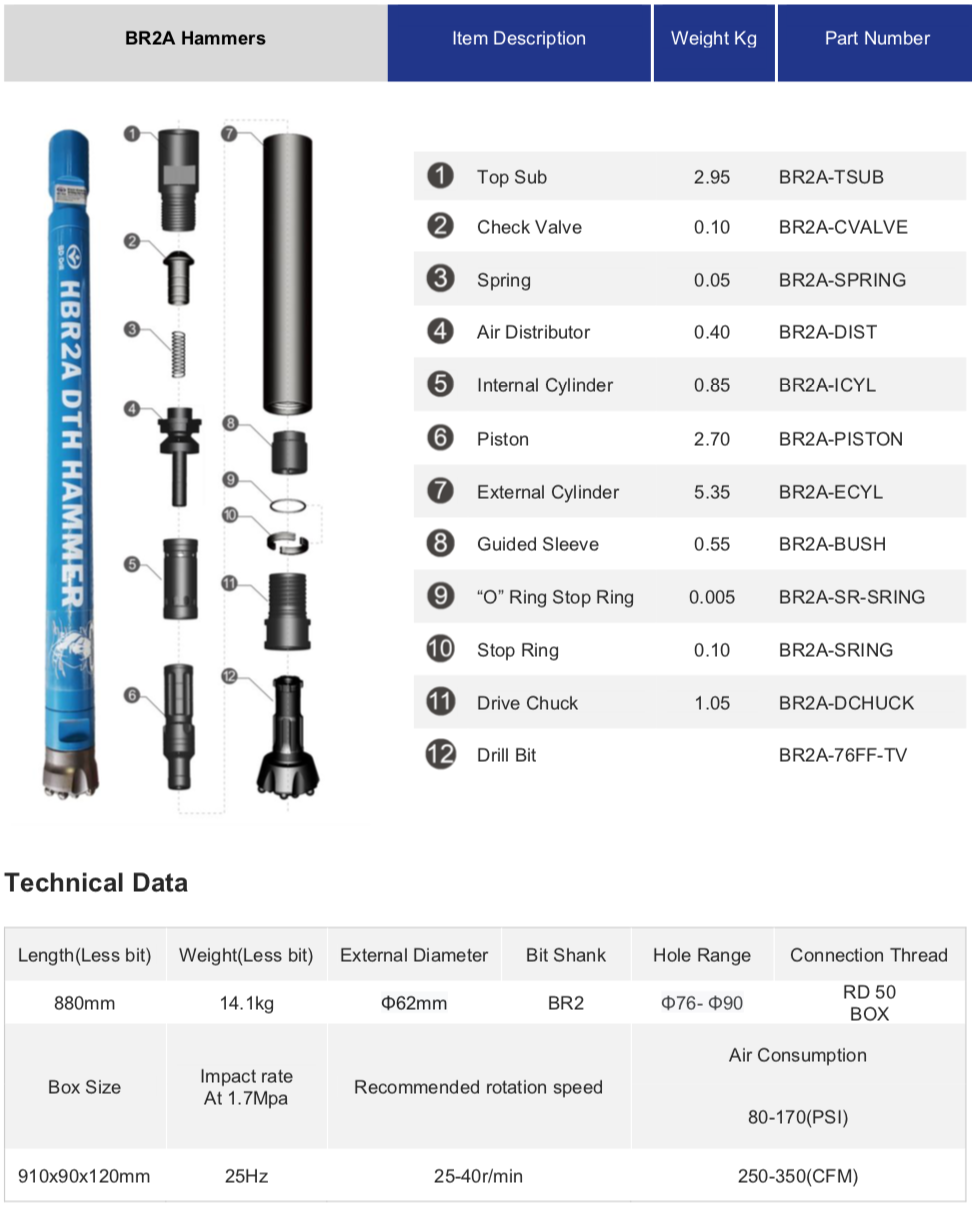

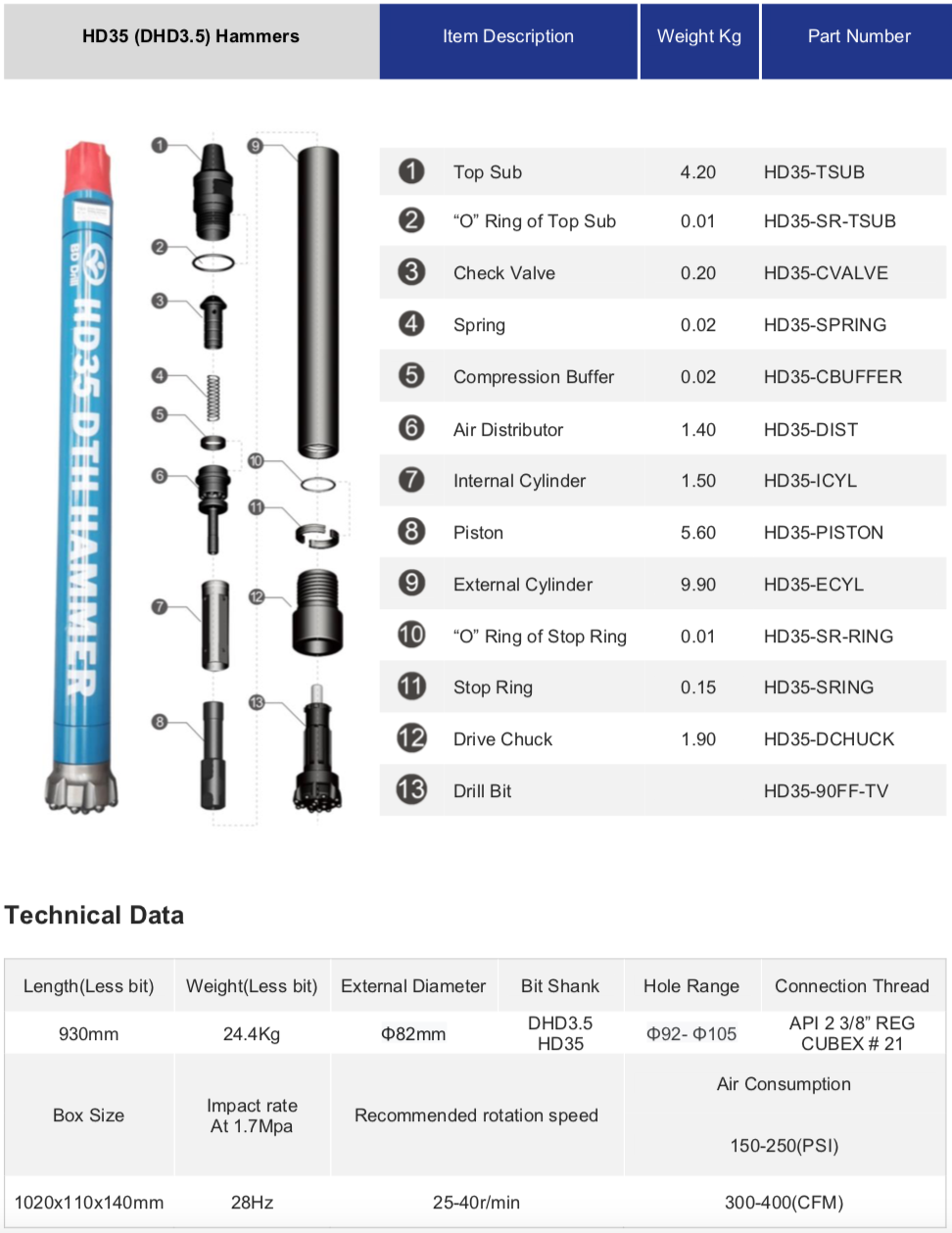

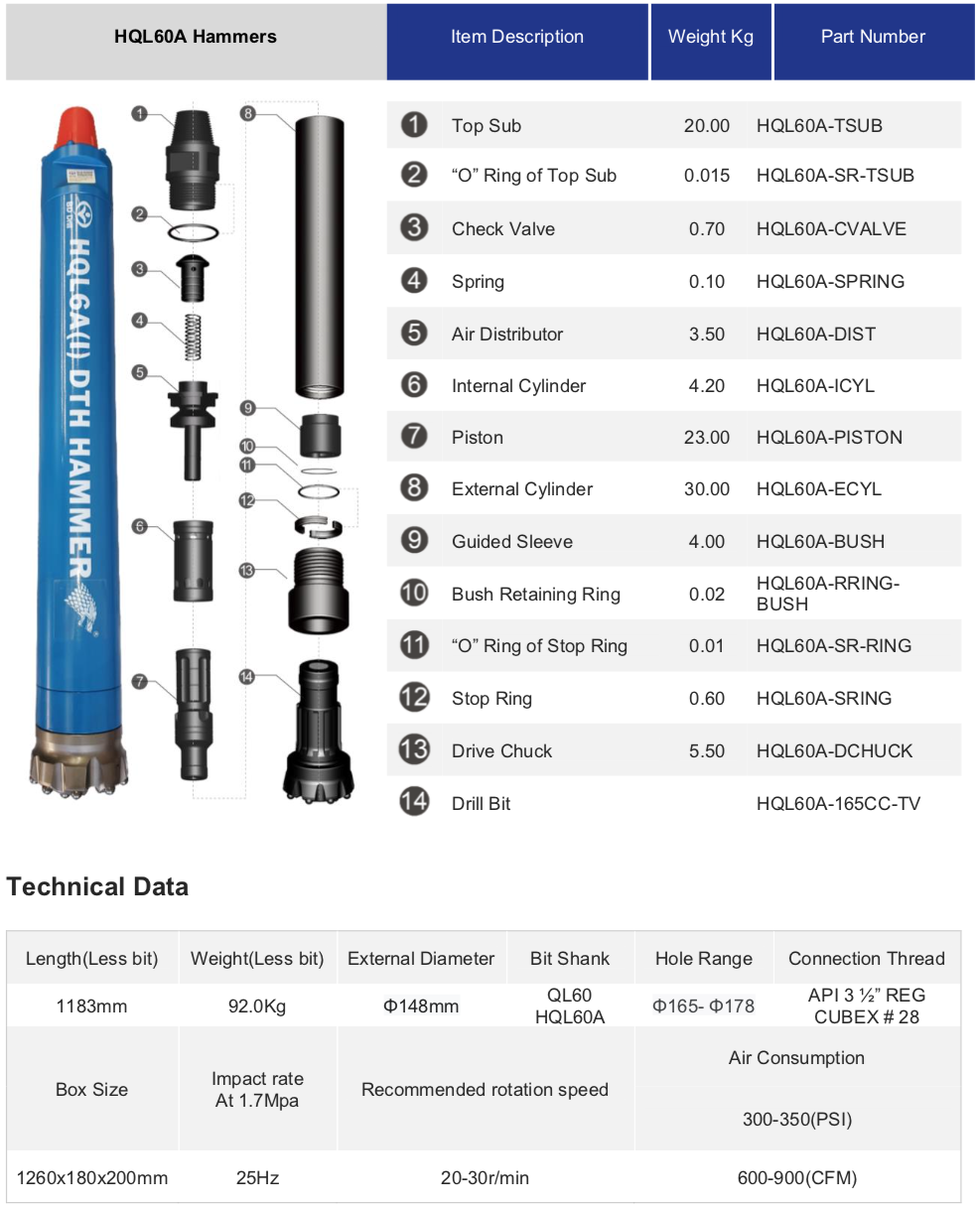

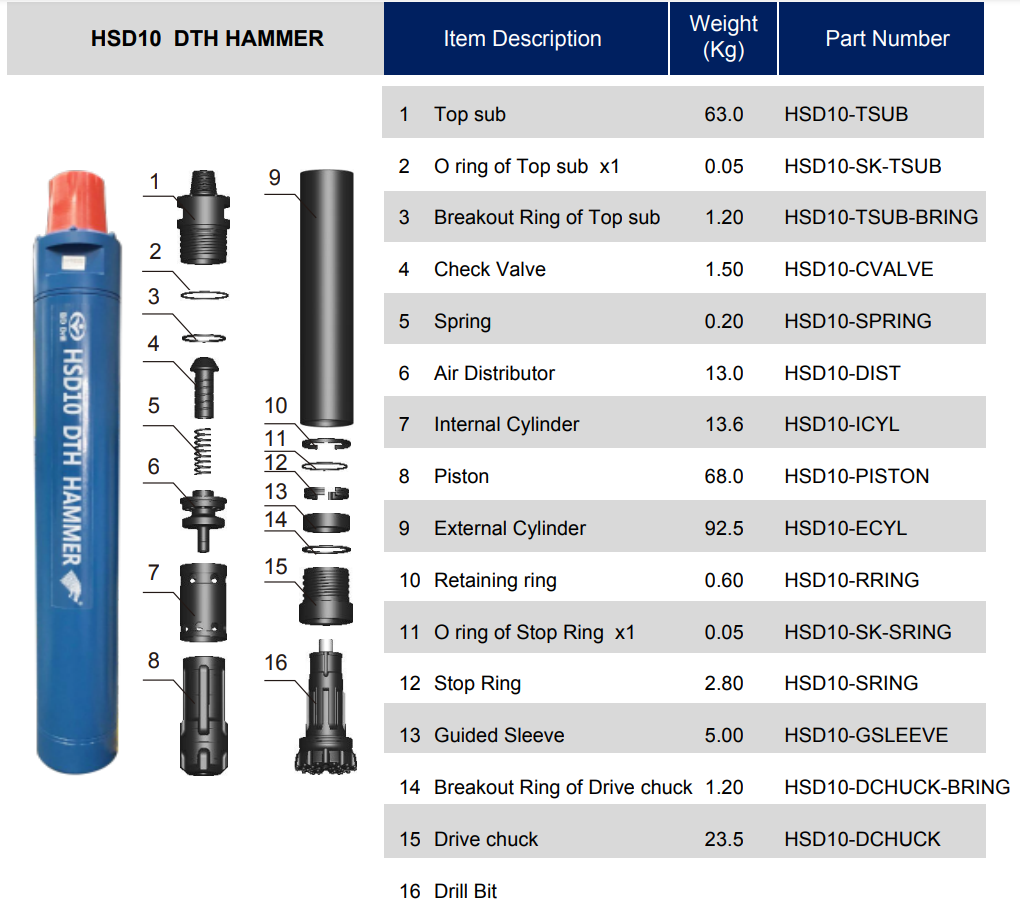

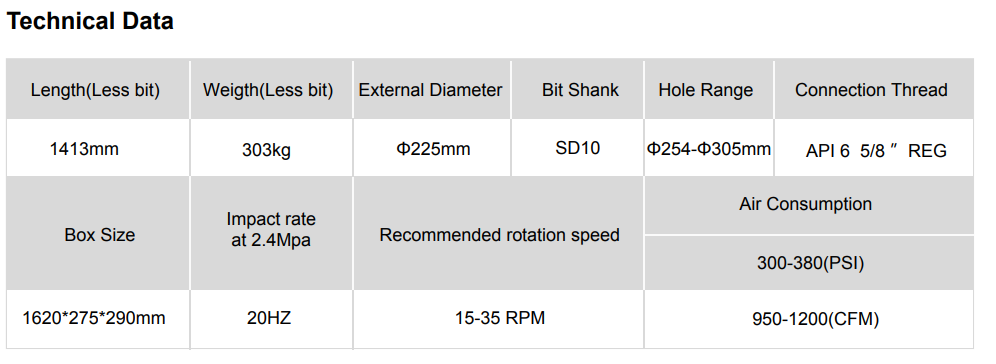

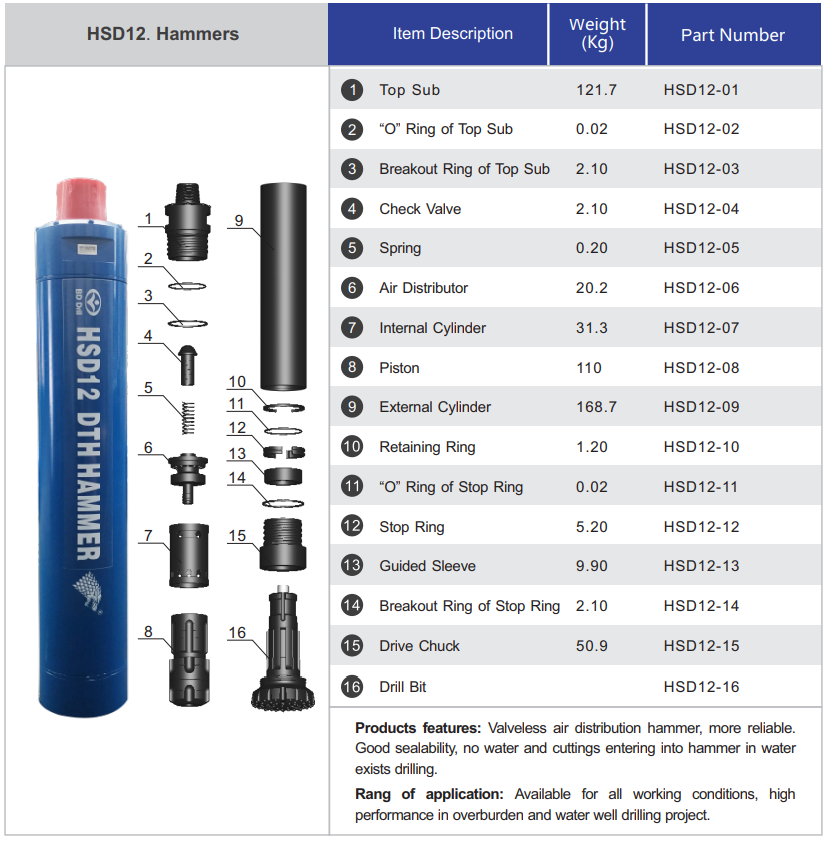

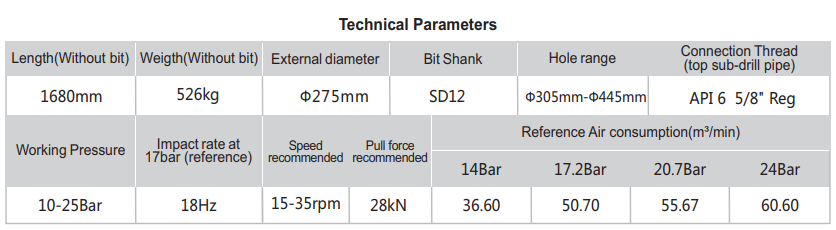

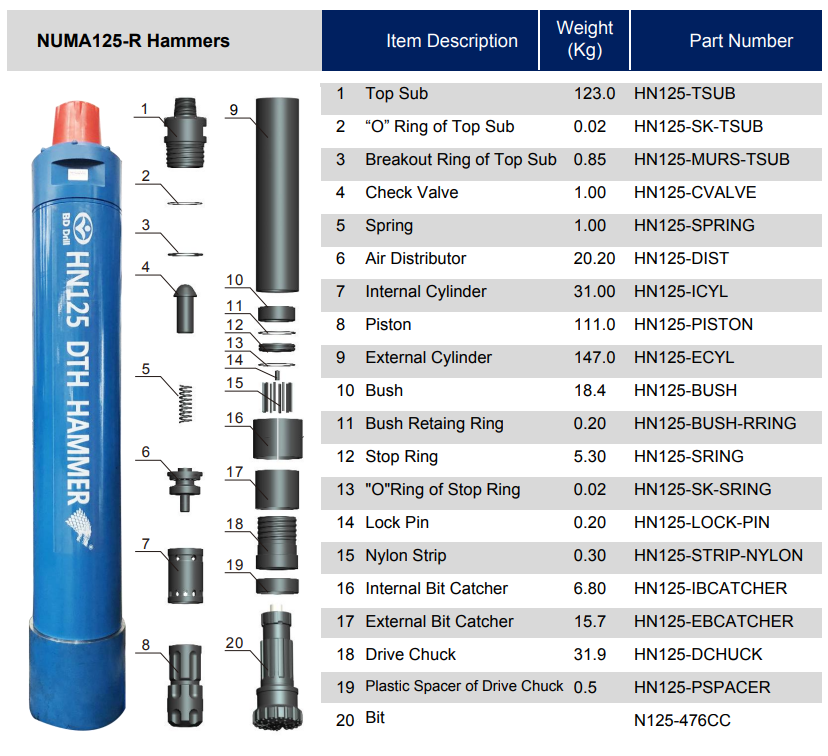

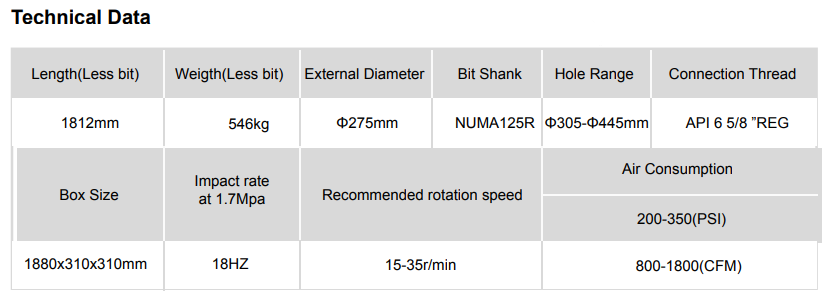

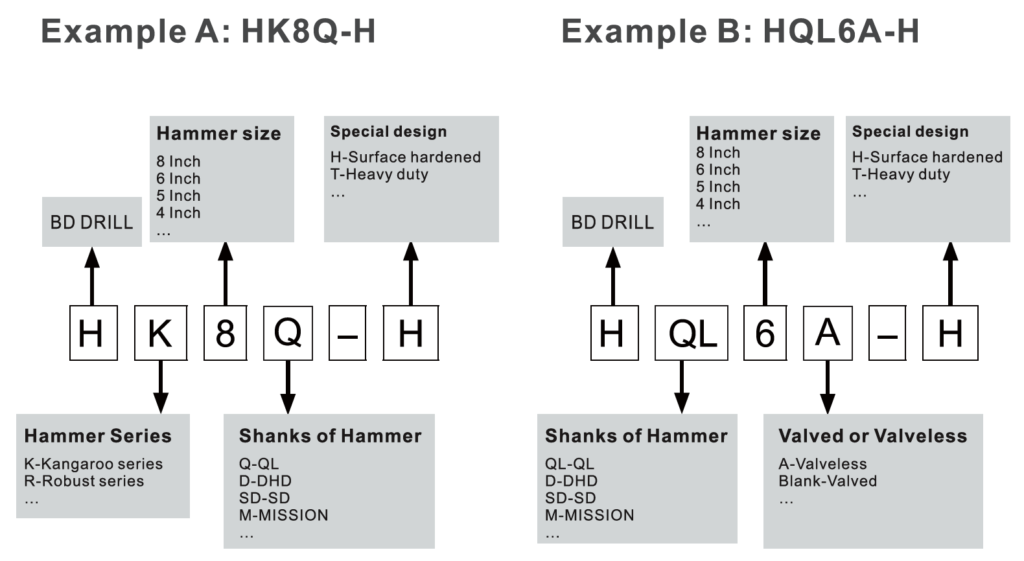

| Hammer | BR2A | DHD3.5 | HK4D | HD45 | HQL4A | HQL50 | HK5Q | HD55 | HQL60 | HQL6A | HQL80 | HD85 | HK9Q | HSD10 | HSD12 | HK12Y | N125-R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recommended bit size, mm | 76 | 92-105 | 112-127 | 140-152 | 165-178 | 203-229 | 216-229 | 245-305 | 305-445 | 305-350 | 305-445 | ||||||

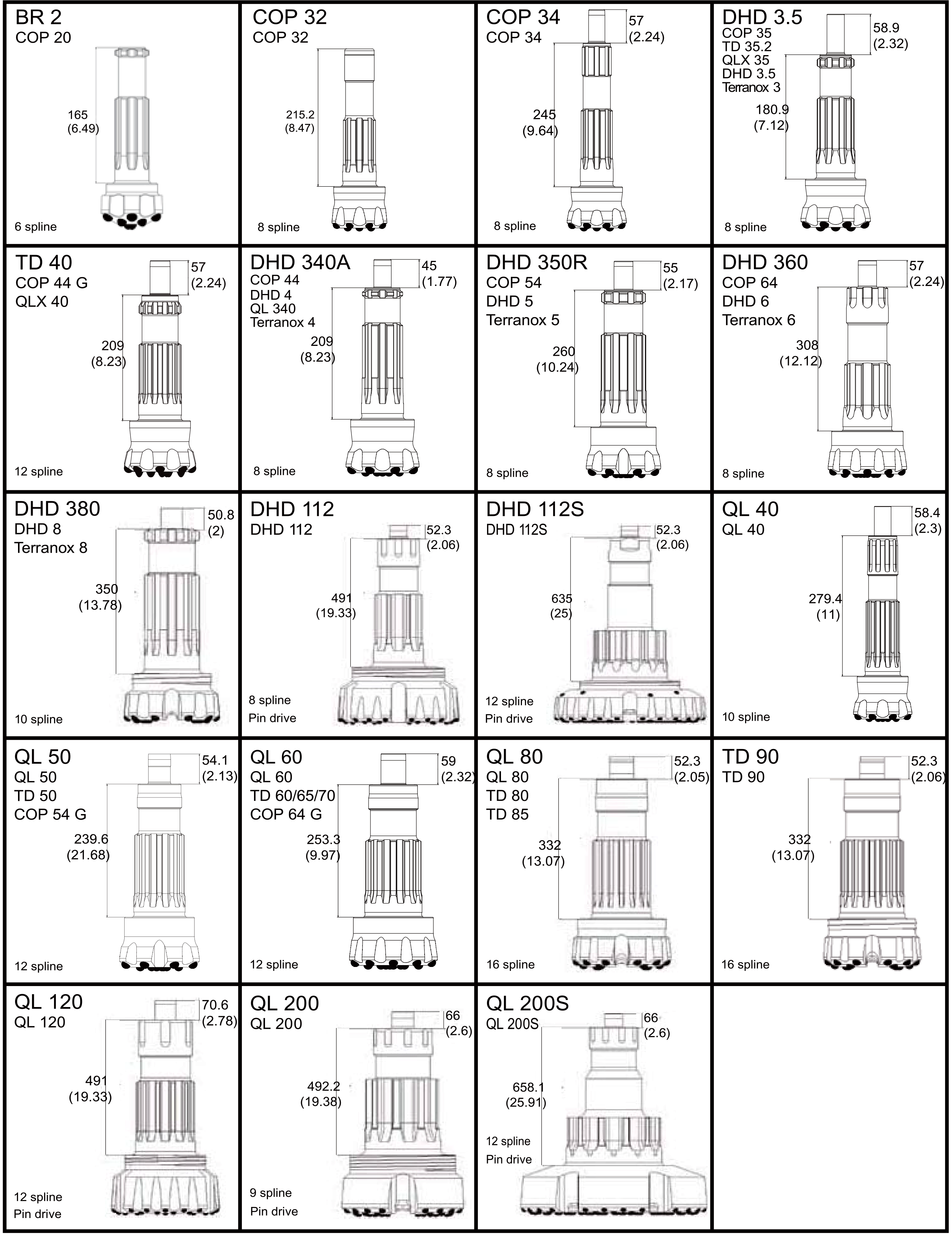

| Bit Shank | BR2A | DHD3.5 | DHD340A | QL40 | QL50 | DHD350 | QL60 | QL80 | DHD380 | QL80 | SD10 | SD12 | HY12 | NUMA125R | |||

| External diameter, mm | 63 | 82 | 100 | 100 | 101 | 126.5 | 127.5 | 126.5 | 148 | 146 | 185 | 185 | 203 | 225 | 275 | 275 | 275 |

| Length excl. thread, mm (Less bit) | 837 | 855 | 915 | 1032.5 | 1057 | 1147 | 935 | 1167 | 1121 | 1182 | 1471 | 1487 | 1345 | 1413 | 1680 | 1590 | 1812 |

| Hammer weight, kg (Less bit) | 14.1 | 25 | 37.5 | 40.6 | 41 | 71.6 | 67.6 | 77.2 | 105 | 105 | 203 | 206 | 228 | 303 | 526 | 510.2 | 546 |

| Package case size | (L)910 (W)90 (H)120 | (L)1200 (W)110 (H)140 | (L)1010 (W)130 (H)160 | (L)1080 (W)125 (H)134 | (L)1150 (W)130 (H)160 | (L)1290 (W)150 (H)175 | (L)1100 (W)155 (H)180 | (L)1290 (W)150 (H)175 | (L)1270 (W)170 (H)200 | (L)1260 (W)180 (H)200 | (L)1440 (W)230 (H)270 | (L)1560 (W)230 (H)270 | (L)1500 (W)240 (H)280 | (L)1620 (W)275 (H)290 | (L)1880 (W)320 (H)320 | (L)1665 (W)320 (H)360 | (L)1880 (W)310 (H)310 |

| Top Sub thread | RD50 | 2-3/8" API REG | 3-1/2" API REG | 4-1/2" API REG | 6-5/8" API REG | 6-5/8" API REG 7-5/8" API REG | 6-5/8" API REG |

||||||||||

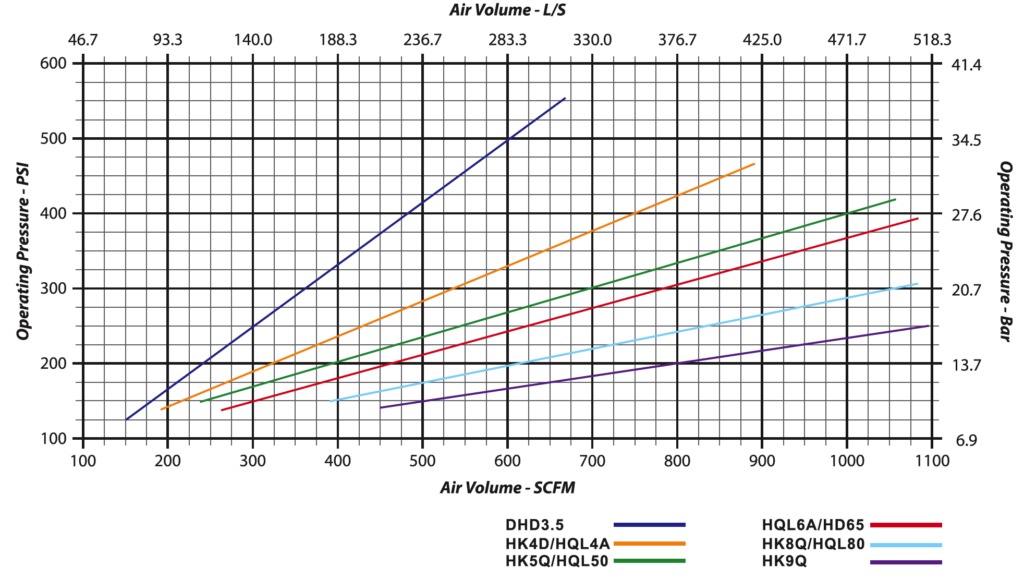

| Working Pressure, PSI | 80-170 | 150-250 | 200-300 | 250-350 | 300-350 | 300-380 | 300-380 | 150-350 | 200-350 | ||||||||

| Air consumption, CFM | 250-350 | 300-400 | 500-700 | 500-800 | 600-900 | 950-1200 | 950-1200 | 1000-1800 | 1200-1500 | 800-1800 | |||||||

| Piston diameter, mm | 42.7 | 65 | 82 | 80 | 80 | 104 | 102 | 100 | 122 | 121 | 150 | 150 | 165 | 185 | 225 | ||

| Piston weight, kg | 1.7 | 5.1 | 9.2 | 9 | 9 | 17 | 17 | 16 | 24 | 24 | 38 | 42 | 50 | 68 | 110 | 111 | 111 |

| Wrench flat, mm | L47 W50 | L57 W35 | L74.5 W45 | L64 W40 | NO wrench flat | L89 W60 | L88 W50 | L89 W60 | L101 W65 | L101 W60 | L128 W70 | L140 W70 | L128 W70 | L140 W70 | L140 W70 | L140 W70 | L140 L70 |

| Feed force, kN | 2~6 | 3~8 | 5~15 | 6~25 | 7~20 | 10~25 | 15~30 | 20~35 | |||||||||

| Rotation speed, r/min | 30-70 | 3-90 | 25-80 | 20-70 | 25-60 | 20-60 | 15-35 | ||||||||||

| Drilling conditions and project specifications may require larger air package to be used | |||||||||||||||||