Top Hammer Drilling

Availability, variety of drill bit designs, and low operating cost make top hammer drilling an advantageous method in many different industries but with the widespread application inevitably follows an equally wide range of demands and challenges.

Versatile and flexible, top hammer drilling is used by various industries all over the world. Arguably, the biggest advantage of top hammer drilling is the size, availability and low cost of drilling rigs.

The rigs can be taken to challenging job locations, drilling contractors usually have machines available with short notice, and they tend to be cheaper than DTH or rotary drilling rigs.

On the drilling consumable side, top hammer drill string is also cost-efficient, fast to set up and, thanks to the wide range of available bit designs, top hammer bits can always be optimised for the ground conditions.

The advantages and possibilities of top hammer drilling do, however, not just mean a broad range of possible applications, but also an equally broad range of clients and demands. Increased automation, longer bit durability and improved efficiency are among the requirements that need to be met by developers.

Ideal for mining and underground operations

Ideal for drilling narrow and short boreholes (down to 1in wide and up to 40m in length) in hard rock, top hammer drills are primarily used in mining, construction, and for quarrying of rock material.

Top Hammer drilling should be the default choice for all holes with a width between 1-1/2 - 4in and a depth of up to around 30m. Ground conditions do not impact so much on the choice of drilling methodology, but it obviously has a great impact on the tool selection. An exception to this is speciality applications like tunnel forepoling, where weak ground conditions mean that forepoling is necessary - which in turn automatically calls for top hammer methodology.

Specifically, the top Hammer method is widely preferred and used in underground mining operations because of the possibility of using water to flush out cuttings. Unlike other technologies, which flush with air, this improves the underground work environment by minimising the impact of drilling dust in the air.

On top of this, top hammer drilling allows for a larger number of smaller holes enabling more accurate and controlled blasting, something which is usually highly critical in underground operations.

Lastly, top hammer drilling is also required for bolting operations to secure tunnels, and, although the drilling machines used for bolting and production drilling can be slightly different, they share the same drilling methodology and require the same skillset from operators.

The challenges and limitations of the top hammer method

While advantageous in many situations, the top hammer method also has its limitations and drawbacks. One of the biggest challenges is the fact that as the drill string loses percussion energy towards the bit, longer rods will lead to a larger energy loss and less efficiency. Speed will slow down towards the end of longer holes, and, at some point, down-the-hole drilling (DTH) will altogether be more advantageous, larger hole sizes and/or deeper holes means that at least DTH drilling should be considered, including the possibility of adding another drill rig type to the operation.

Additionally, the repeated shock waves from the hydraulic hammer on couplings and rods of top drifter drill strings create continuous wear on components, meaning that top hammer drills usually require more consumables in the long run. This also goes for drill bits which, with traditional bits, may need to be changed or sharpened several times during a work session. The requirement for manually operated replacements or upkeep, in turn, works against one of the strongest demands within the industry, especially in underground drilling, namely the demand for greater automation.

On top of this, top hammer drilling allows for a larger number of smaller holes enabling more accurate and controlled blasting, something which is usually highly critical in underground operations.

Lastly, top hammer drilling is also required for bolting operations to secure tunnels, and, although the drilling machines used for bolting and production drilling can be slightly different, they share the same drilling methodology and require the same skillset from operators.

New solutions and old skills

One of the requests most often voiced by drill operators is for automated and remote-controlled drilling machines capable of drilling an entire work session before being removed for the blasting operation. But while control systems might theoretically enable this, new solutions are necessary for consumables to practically allow it.

Flexible and fast to set up top hammer drills are ideal for narrow and short boreholes in hard rockFlexible and fast to set up, top hammer drills are ideal for narrow and short boreholes in hard rock

"The traditional drilling bits can't last long enough, but Robit developed special bits with diamond coated carbides that can perform in the desired way. That means one drill bit being able to drill typically about 3,000 - 3,300ft (900 - 1,000m), and it will be able to maintain the drilling performance well all the way towards the end of its life without sharpening," says Vuojolainen. "While the diamond bit unit cost is clearly higher than a usual TH bit, it does offer an extremely good total cost per metre payback."

Together with the general improvements in the durability of drilling consumables, operators' ever prevalent desire to improve efficiency and the consequent continuous increase in drilling power are also creating new demands to the drilling string, especially the threads. As a response, the market is seeing new thread designs, like for example shoulder supported male/female thread, that many operators have found an improvement to the traditional thread designs.

However, it is not one specific innovation or application which will decide the efficiency and profitability of top hammer drilling on a specific project. Rather it is, stresses Vuojolainen, the old skill of adding up all cost-determining factors and establishing the total drilling cost (TDC). "TDC is a sum of productivity cost of drilling in terms of time and cost per metre (drill string endurance)," he explains.

Energy saving is another key factor as sometimes drilling is set-up to drill with highest pressures, while not necessarily needed. In short, Vuojolainen concludes, what needs to be focussed on is what can be done to increase productivity by increasing drilling speed, avoiding downtime and managing the lifetime of wear products.

On top of this, top hammer drilling allows for a larger number of smaller holes enabling more accurate and controlled blasting, something which is usually highly critical in underground operations.

Lastly, top hammer drilling is also required for bolting operations to secure tunnels, and, although the drilling machines used for bolting and production drilling can be slightly different, they share the same drilling methodology and require the same skillset from operators.

Top hammer drilling the method

The main distinction between the top hammer method and the down the hole (DTH) method is the placement of the percussive force within the appliance. In top hammer drilling, the activity is concentrated at the top of the drill string, above the hole, as a hammer transmits cyclical shock waves to the drill bit by applying a percussive force on the drill rods or tubes (With DTH drills, the hammer is placed down-the-hole at the bit). The percussive system strikes the drill rod with 2,000 - 5,000 strikes per minute and the rotation speed can be 60 - 200 rounds per minute. The cuttings are flushed up from the bottom of the hole with pressurised air or water.

Bit types

This section provides general descriptions, guidelines and recommendations for top hammer drilling bits

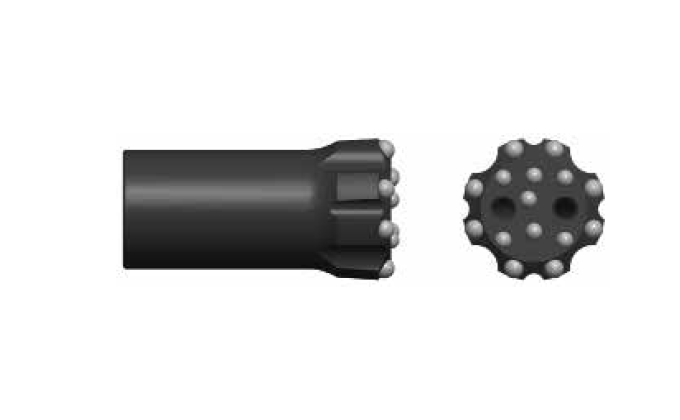

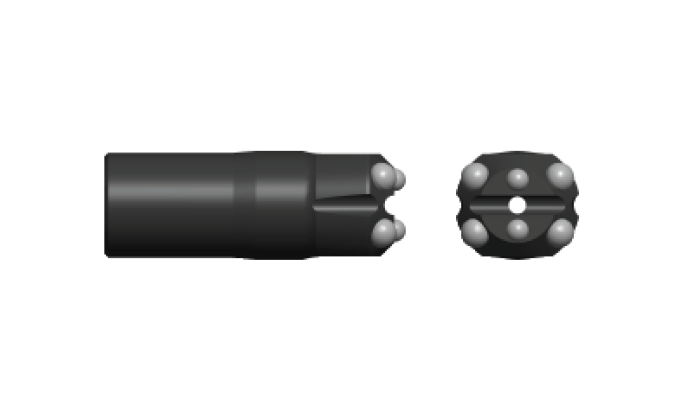

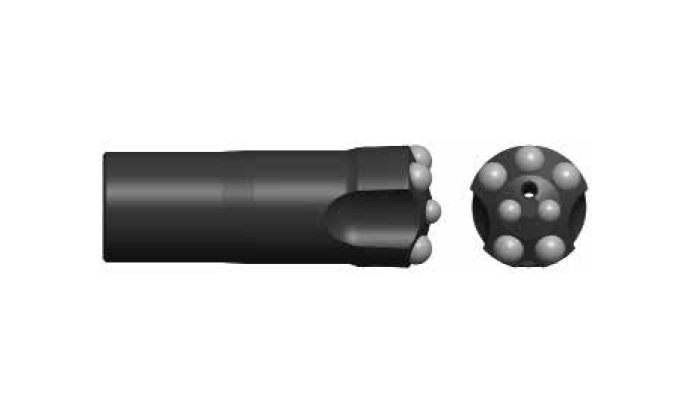

Button Bit

- Fast penetration

- More adaptable to different types of ground conditions due to the different configurations of design and available buttons

Blade Bit

- Maintains hole diameter with reduced gauge wear

- Reduces hole deviation

- Different types of carbides are available for varied ground conditions

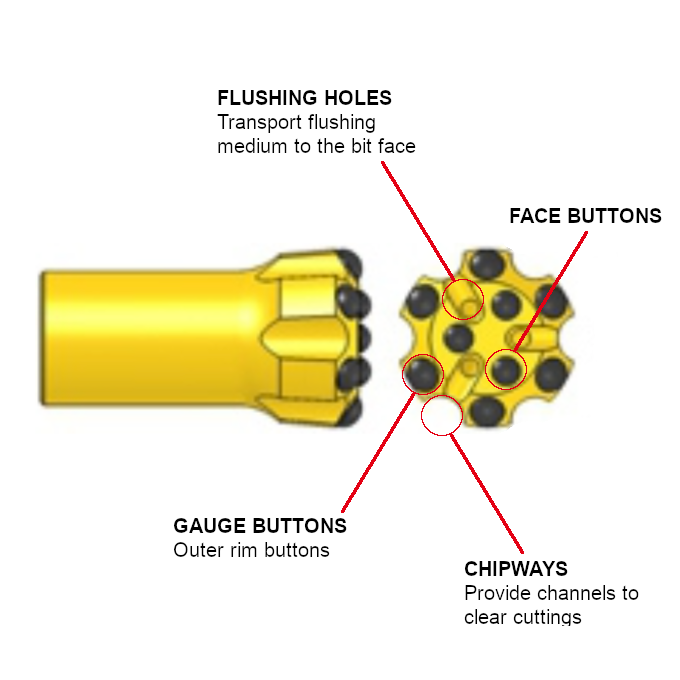

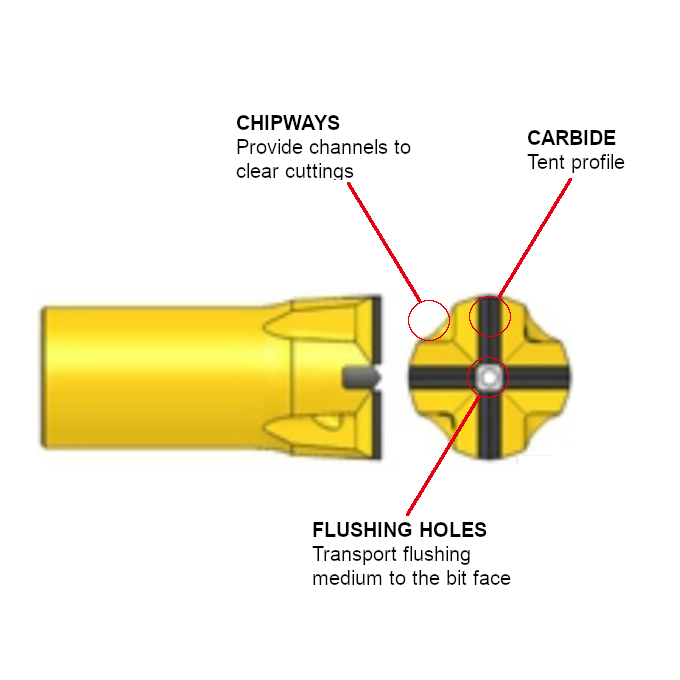

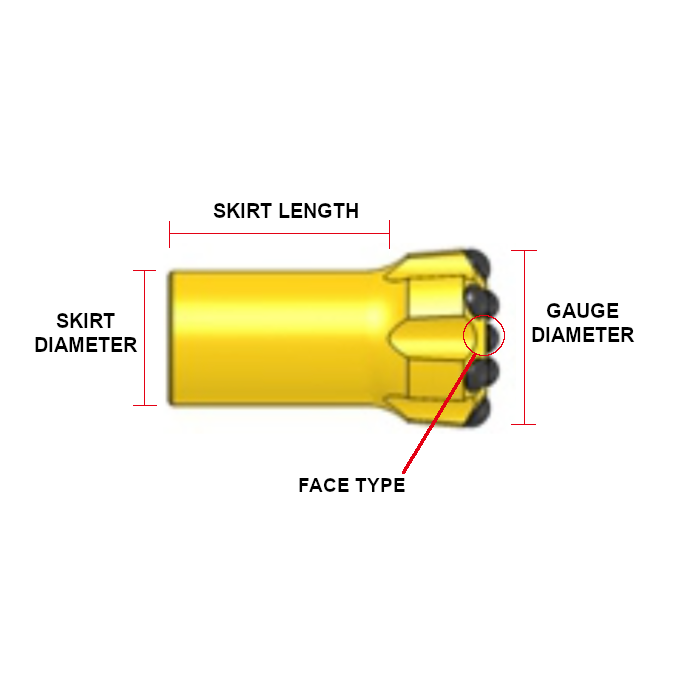

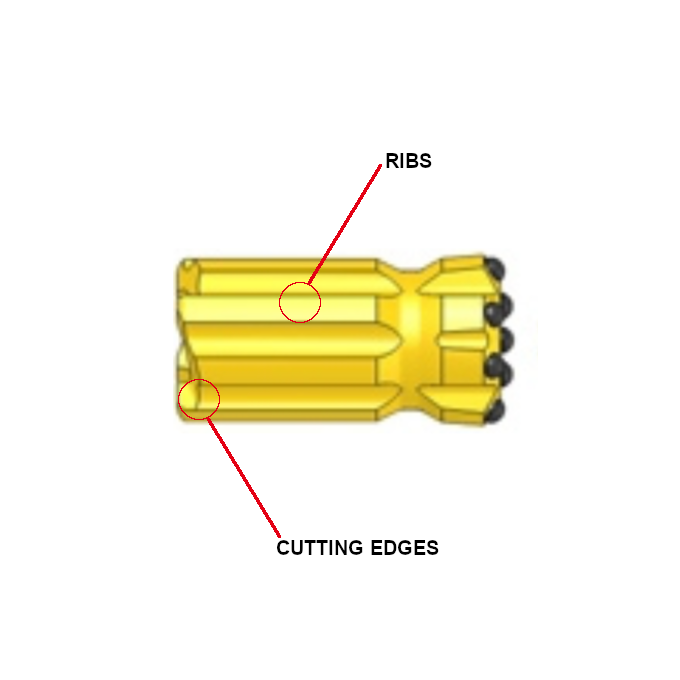

Button Bit Components

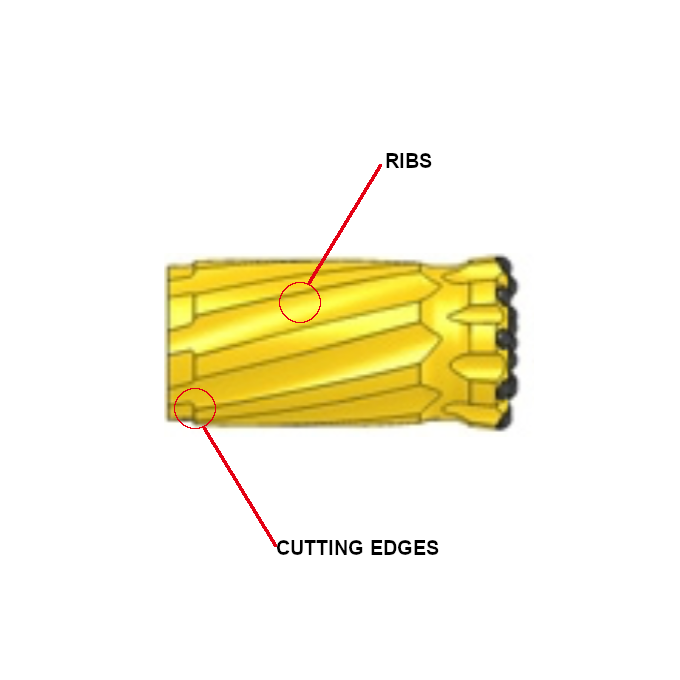

Special Skirt Designs

Retrac Angled Bit

- Angled design for full contact, reduced hole deviation

- Cutting edges incorporated into the skirt

Retrac Straight Bit

- Cutting edges in the skirt for easy removal of bit in adverse conditions

Bit Face Designs

BR - Button Recessed

"Drop Center" face characteristic

- Reduced hole deviation

- Broken ground conditions

BF - Button Flat

"Flat" face characteristic

- Generic purpose

- Hard to medium conditions

BC - Button Chisel

Chisel face characteristic

- Fast penetration

- Abrasive conditions

BD - Button Dome

Dome face characteristic

- Clearly defined raised face profiles

- Primary reaming applications in soft ground

Button Types

Round Button

- Best suited to hard ground

- Abrasive to very abrasive applications

- 25,000 to 45,000 PSI (170 to 300 MPa)

Sharp Button

- Best suited to non-abrasive ground

- Fast penetration

- Suitable for smaller diameter bits

Ballistic Button

- Suitable for non-abrasive ground

- Fast penetration

- Suitable for smaller diameter bits

- Small contact area

Semi Ballistic Button

- Suitable for medium mildly abrasive ground

- Fast penetration

- 15,000 to 25,000 PSI (100 to 170 MPa)

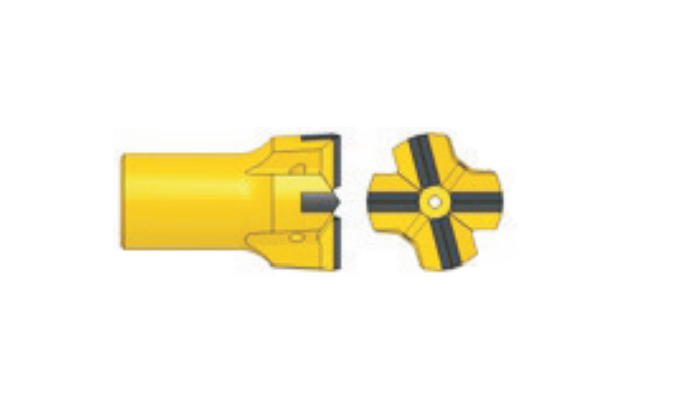

Blade Bits

Blade bit designs are limited to X and cross type face configurations

Blade bits larger than 57mm are usually in 'X' configuration, smaller blade bits are in the cross configuration.

Blade bits are used when hole accuracy is required in very hard and abrasive ground. They are more durable than button bits.

Cross Bits

- Easier to sharpen than 'X' bits, the inset angles are equal of all four sides

- In certain rock conditions, cross bits can produce a spiraled 5 sided hole.

'X' Bits

- 'X' bits tend to drill round holes in all rock conditions.

- The steel support in the narrow parts of the X becomes inadequate in X-bits smaller than 64mm because of the restrictive circumference.

Reaming Bits

Pilot holes are drilled to required depth and then reamed out to the larger diameter in a second pass. This technique is used when the hole diameter exceeds the capabilities of the rockdrill and drilling tools available.

Reaming Bits

- Large diameter service holes form level to level for drainage, electrical cables or pipelines

- Reaming cut holes for development rounds and long hole blasting

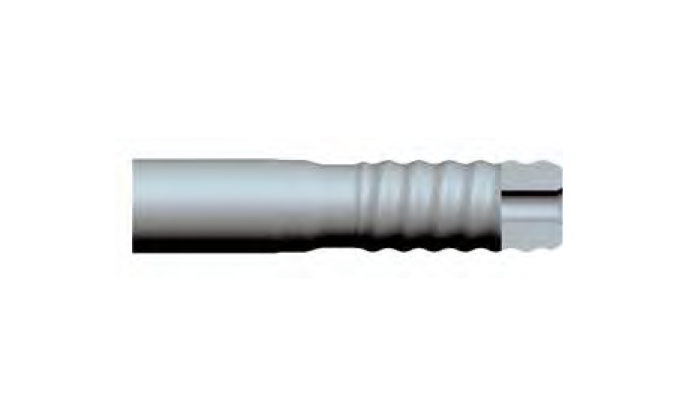

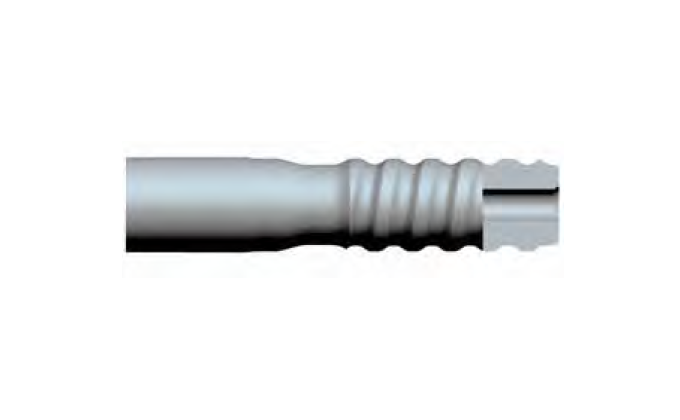

Rod Types

Round Rods

- Lighter than hexagonal rods of the same size

- Used in extension drilling applications

- Measured by external diameter

Hexagonal Rods

- Cross sections are more rigid, heavier and transfer energy more efficiently

- The rigid cross section allows for a larger thread

- The angles of the design creates more turbulence which keeps heavier cuttings moving

- Measured across the flat

Carburization

- The entire surface of the rod is hardened providing protection on both internal and external surfaces.

- Primarily used in underground applications where liquid is used as a flushing medium

High Frequency Induction

- Only the thread ends of the rod are hardened

- Primarily used in surface drilling applications where air is the flushing medium

Thread Types

R (Rope) Thread

- Rope threads - low pitch, 12.7mm and a small angle of profile

- Sizes: 22mm - 38mm

- Good wear properties

- Ideal for single pass or short hole drilling such as underground tunneling applications that require infrequent uncoupling

(T) Thread

- "T" thread - larger pitch and larger angle of profile

- Sizes: 35mm, 38mm, 45mm and 51mm

- Excellent wear properties and good coupling properties

- Ideal for extension drilling with multiple steel drill rods

- Greater torque capacity

Sources

https://www.geodrillinginternational.com/underground-drilling/news/1383459/down-with-the-top-hammer-method