Single Pass Drilling

Large rotary drills have been in use for years around the world in mining applications. In many open pit operations, these large drills were equipped with electric power and long towers for drilling benches in a single pass. Today, these features are being driven to smaller equipment. Let’s look at the benefits of single-pass.

The drilling of large diameter holes, generally considered to be greater than 9″ in diameter, is done predominantly with rotary blasthole drills.

One of the reasons for this is that larger diameter tricone bits allow for large bearings to handle high pulldown forces to drill through hard rock quickly. These high pulldown loads require a heavy tower structure to transmit these pulldown forces to the drill bit. Further, this high pulldown must be offset by sufficient mass to keep the drill rig from lifting off the ground. The resulting rig is therefore quite heavy.

With a heavy, durable rig already dictated by a large hole diameter, drill designers are able to take advantage of the large platform to offer longer towers capable of drilling benches in one pass.

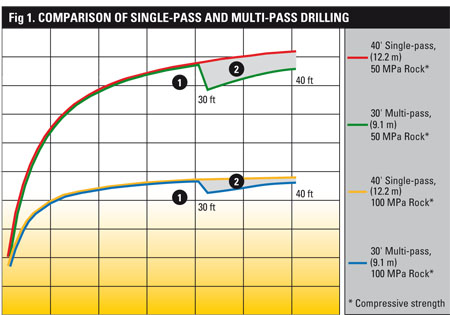

This often drives a change in structural design and supporting components such as undercarriages, but the basic rig envelope doesn't change. Drilling a hole in one pass has many advantages.