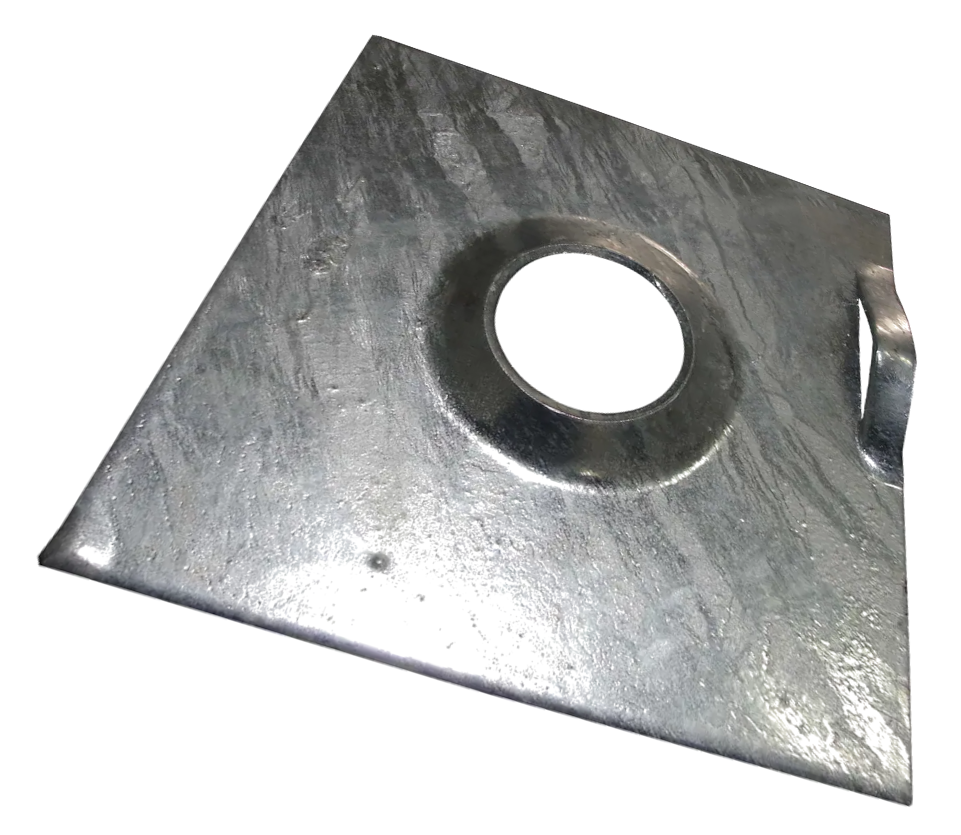

Ground Support Dome Plates

Black Diamond Drilling manufactures high load bearing capacity dome plates that provide optimum support in a wide range of rock conditions.

Dome plates are available in a range of sizes to suit most bolt types and sizes and come with or without the hanger loop. Galvanized for extended durability and load rated from 80 to 145kN.

Dome plates are primarily used in the securing strata in underground mining. It is essential to have a quality product reinforcing the dangerous surfaces of an underground mine. Black Diamond Drilling Dome Plates have been rigorously tested to provide the best protection for Underground Mining applications

KEY ADVANTAGES

Galvanised dome plates play a crucial role in underground mining ground support systems. They are used in conjunction with rock bolts to help stabilise the rock surface and prevent falls of ground. When galvanised, these plates gain additional advantages, particularly in harsh underground environments.

• Corrosion Resistance - Galvanisation involves coating the plate with a layer of zinc, which protects the steel from corrosion. This is especially important in wet or chemically aggressive underground environments, such as areas with groundwater and high humidity.

• Extended Service Life - Galvanised plates last longer than non-coated plates, which is vital for long-term infrastructure areas like declines, portals, pump stations, and refuge chambers. Reduces the need for replacement, lowering downtime and material costs.

• Improved Safety - Dome plates maintain their strength and load-bearing capacity over time, ensuring ongoing rock stability and reducing the risk of rock falls or collapses. Maintains plate performance even in areas with ground movement or vibration.

• Better Load Transfer - The dome shape allows for a more centralised and even transfer of load from the bolt to the plate and then to the rock. Helps prevent bolt head pull-through and reduces the risk of plate distortion under high loads.

• Compatible with Mesh - Dome plates are commonly used in combination with welded mesh, helping to clamp the mesh tightly to the rock surface and prevent it from sagging.

• Durability During Handling and Installation - The zinc coating provides a tough surface that resists scratching, chipping, and wear during transport and installation. Even if the coating is scratched, the zinc provides sacrificial protection to exposed steel.

| Product Code | GR-DPLATE-SS39-125/125-G | GR-DPLATE-SS39-150/150-G | GR-DPLATE-SS47-150/150-G | GR-DPLATE-SS47-200/200-G |

| Bolt Type | GR-SSET-33-GALV | GR-SSET-39-GALV | GR-SSET-47-GALV | GR-SSET-47-GALV |

| Plate Dimensions | 125x125mm | 150x150mm | 150x150mm | 200x200mm |

| Plate Thickness | 4mm | 4mm | 4mm | 4mm |

| Height | 18mm | 25mm | 25mm | 25mm |

| Hole Size | 36mm | 43mm | 49mm | 49mm |

| Yield Strength | 240-370MPa | 240-370MPa | 240-370MPa | 240-370MPa |

| Tensile Strength | 340-380MPa | 340-380MPa | 340-380MPa | 340-380MPa |

| Max Plate Load | 79kM | 108kN | 147kN | 147kN |

| Weight | 0.49Kg | 0.71Kg | 0.75Kg | 1.3Kg |

TYPICAL APPLICATIONS

Black Diamond Drilling Galvanised Dome Plates are a premium component for multi layered ground support systems and are used for:

• Development headings, declines and drifts.

• Reinforcement of mesh for surface control in underground mining.

• Areas subject to high humidity or corrosive water.

• Long-life mines or infrastructure areas such as refuge chambers and conveyor drives.

If you're specifying or supplying ground support products for underground mining, using galvanised Dome plates adds long-term value by improving safety, performance, and cost-effectiveness in challenging underground conditions.